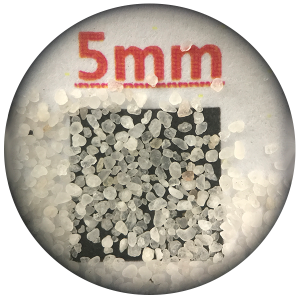

- Ceramsite

As a new artificial silica sand with a ball shape, ceramsite has high refractoriness and as its heat expansion rate is low, can gain precise casting. Also, compared to chromite sand and zircon sand, it increases the quality of casting and as it can reduce the cost and is environmentally friendly sand, it will be the best choice if applied to the foundry.

| Item | Al2O3 | Fe2O3 | AFS GFN | Application |

|---|---|---|---|---|

| Ceramsite300# | 75% | 3% | 25~29 | Cast iron, Cast steel |

| Ceramsite400# | 75% | 3% | 35~39 | Cast iron, Cast steel |

Size : 30#, 40#, 50#, 60#, 65#, 75#

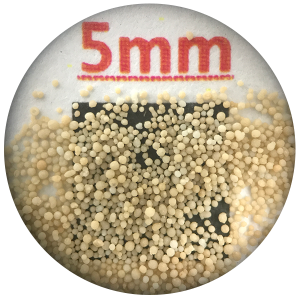

- CPS

As a new artificial silica sand that is ball shaped, CPS (Ceramic Power Sand) has high refractoriness and as its heat expansion rate is very low, a precise casting can be gained. As a next generation artificial sand that can solve resource depletion problems and environmental problems, it is an epoch-making sand that can replace most sand being used now.

| Item | Al2O3 | SiO2 | Fe2O3 | TiO2 | MgO | CaO | K2O | Application |

|---|---|---|---|---|---|---|---|---|

| CPS-1 | 44.9% | 48.2% | 3.0% | 0.8% | 0.3% | 0.7% | 0.15% | Cast iron, Cast steel |

| CPS-2 | 51.9% | 43.9% | 1.1% | 0.7% | 0.3% | 0.54% | 0.14% | Cast iron, Cast steel |

Size : 30#, 40#, 50#, 55#, 60#, 65#, 75#, 85#

- Australia sand

It can cut down consumption of resin and catalyst as its particle form is circular and it a sand that is very appropriate for use as furan sand.

| Item | SiO2 | Al2O3 | CaO | Fe2O3 | TiO2 | K2O | Na2O |

|---|---|---|---|---|---|---|---|

| Australia sand | 99.3% | 0.026% | 0.002% | 0.006% | 0.025% | 0.001% | 0.001% |

Size : 20#, 25#